-

Introduction

After more than ten years of research and development, China''s basalt fiber production technology and equipment have been in the forefront of the world. several typical applications of basalt fiber core road products in highway engineering projects are to be introduced in the 6th chapter.

Q6

Please introduce several major physical engineering applications and construction of test sections. Is there any long-term observation data? What conclusions can be drawn from these data?

Chopped basalt fiber reinforced Asphalt concrete pavement

Chopped basalt fiber for asphalt concrete is a kind of chopped fiber having good binding with asphalt by special surface treatment and chopping.

01 Overlay maintenance of Hang Jin Qu Highway

Implementation No.: k143+512~k144+141, Continuous uphill section with 3% longitudinal gradient

Damage analysis: Pavement damage presents rutting only. Through the core sampling analysis, the design of the mix ratio of the upper asphalt mixture is unreasonable, the asphalt content is high, and too many the aggregate chips and mineral powder at the rut.

Implementation plan: A certain amount of basalt fiber is added to SBS modified asphalt AC-13C overlay.

Detection data

(1)The dynamic stability of asphalt concrete is increased by 21%.

(2)99% compaction

(3)Average seepage coefficient 163ml/min

(4)Average BPN value 72BPN

(5)Tectonic depth detected by sand-laying method is 0.69mm

Conclusion: Asphalt concrete with basalt fiber greatly improves the high temperature stability of the pavement, has good durability, reduces the phenomenon of secondary rutting, improves the service life of the pavement, and reduces the maintenance cost.

02 Highway G4 Overhaul Project

Time: in 2013

Section: k1641+500~k1841+763

Implementation plan: “White+black” pavement, chopped basalt fiber is used for the first time to resist reflective cracks in the middle surface layer.

Conclusion: Road capacity, driving safety, comfort, and maintenance convenience are qualitatively improved

03 Qiqihar to Daqing Highway

Time: in 2009

Section: K762-K772 single carriageway road using basalt fiber AC-16

Detection time: April 2018

Detection result: The sections without basalt fiber have been renovated and reconstructed, and basalt fiber sections are still in use.

04 Test section of basalt fiber BFSMA in Changchun outer ring road

Construction time: Sep. 2017

Test time: April 2018

Test results: the indexes such as flatness, tectonic depth and number of cracks were significantly better than the lignin fiber SMA section implemented in the same period

05 Jilin Huinan-Baishan Highway

Time: May 2018

Implementation plan: BFSMA asphalt pavement

Section length: 30km

Test result: all the indexes met the standard requirements, and the skid resistance was obviously better than the lignin fiber SMA section

06 Beijing-Shanghai Highway Special Rectification Project

Damage analysis: net-shaped cracking and repairing

Implementation plan: Since 2013, basalt fiber asphalt mixture has been used in Beijing-Shanghai Highway Special Rectification Project. Accumulated 88.2km in four years

Implemented section 1: in 2013, special treatment was carried out for the K958+336~089 section of the Shanghai-Beijing direction and the K961 section of Beijing-Shanghai to the direction of the downramp, totaling 1.563km

Implemented Section 2: in 2014, pavement overlay project was carried out in the Beijing-Shanghai highway Xusui section, Huai’an section, Yangzhou section and Qiyang section, with a total of 44 sections, totaling 11.3km of single lane.

Implemented Section 3: in 2015, basalt fiber modified asphalt mixture pavement in Beijing-Shanghai Highway Special Rectification Project, a total of 312 sections and 45.3km of single lane.

Implemented Section 4: in 2016, basalt fiber modified asphalt mixture was used in Jiangsu Beijing-Shanghai Highway Special Rectification Project, a total of 200 sections and 25km of single lane.Chopped basalt fiber reinforced Cement concrete pavement

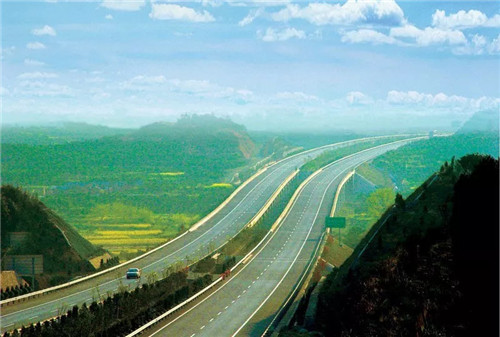

Chopped Basalt fiber for cement concrete is short-cut inorganic mineral fiber from corresponding continuous basalt fiber, which is less than 50mm in length and can be uniformly dispersed in cement concrete or mortar.

01 Shuangnen highway toll station

Test time: April 2018

Test result:

(1)Ordinary cement concrete and steel bars have more cracks,net-shape cracks and more wear on the surface.

(2)The basalt fiber cement concrete and basalt fiber rebars are mainly single transverse cracks, the crack width is not much different, and the concrete slab surface wear is less.

02 Bridge deck paved with concrete

Test result:

The overall operation effect of Jilin Nendan Highway and Changchun beltway bridge is stable, the asphalt overlay is smooth and has no cracks, and there is no obvious leakage under the bridge.

03 Yongxiang tunnel repair and reinforcement project

Test data

(1)Basalt fiber can obviously improve the rebound of shotcrete and the loss rate of steel fiber. The rebound rate is reduced from 34.6% to 28.3%, and the steel fiber loss rate is reduced from 12.22% to 7.08%.

(2)Primary lining is reduced by 20% compared with the ordinary concrete, and the safety factor is increased by 54%.

Conclusion and evaluation

(1)Improve the compactness and spray speed of concrete

(2)Effectively reduce displacement of surrounding rock

(3)Reduce the thickness of the primary lining and the amount of masonry, simplify the process, reduce the cost of construction, improve the durability of the structure, extend the service life

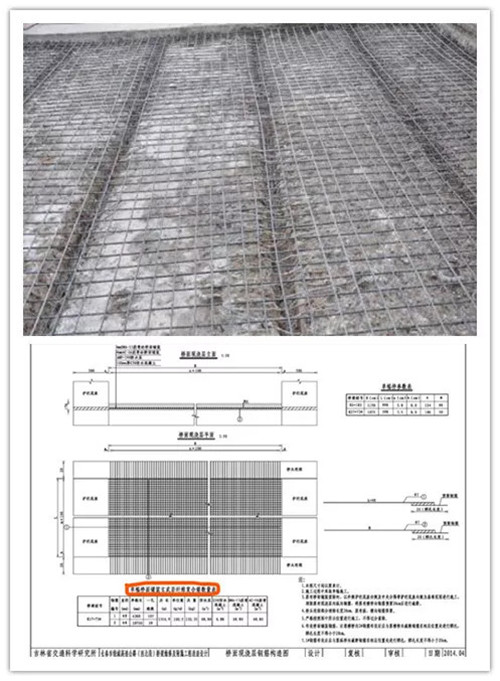

04 Rural road in Panshi

Implementation plan

In Oct.2016, rural road in Panshi, total length 4.2km, using C30 cement concrete.

Basalt fiber rebar

Basalt fiber rebar is a new type of building material that is produced continuously by using high strength basalt fiber and vinyl resin (epoxy resin) through pultrusion, winding, surface coating and composite molding.

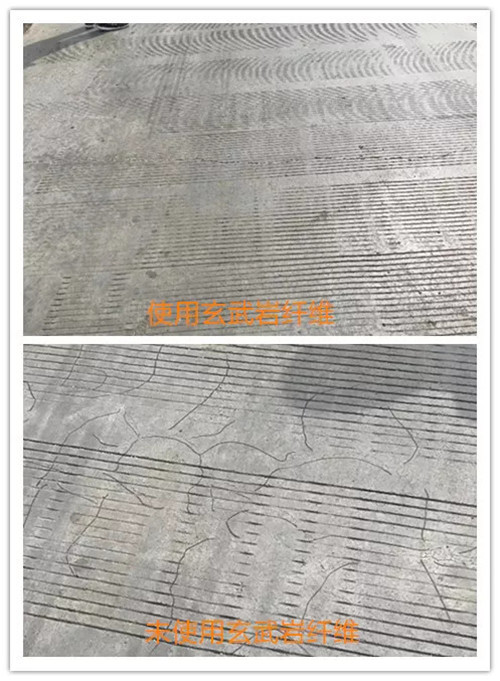

01 Nendan Highway Bridge deck project

Conclusion and evaluation

(1)To solve the problem of large amount of lapping in bridge deck pavement, shorten the construction period by 60% and save labor cost

(2)Compared with the ordinary concrete bridge deck constructed in the same period, the crack is reduced by 30% and the maintenance cost is also reduced

(3)Light weight, convenient transportation, easy operation, simple construction, and saving labor costs

02 Zhangshi Highway

Time: May 2008

Implemented Section: The total length is 652.9M, on the north and south sides of the bridge.

Implementation plan:

(1)No lapping, no welding point continuous reinforcement construction

(2)The transverse bars and supports are all 16mm steel bars, while the longitudinal bars are 10mm and 8mm basalt fiber threaded bars

(3)reinforcement material 10mm 274m/roll, 8mm 342m/roll

Conclusion and evaluation

(1)if all longitudinal bars are 16mm steel bars, then needs 565tons and the cost will increase by 28%

(2)In addition to the increase in transportation volume, the welding workload is heavy, the construction time is long, and other costs increased.

(3)Effectively reduce shrinkage cracks in concrete pavement slab, extend service life and save cost

03 Tianshui seismic station

Implementation plan: Composite bars replace copper bars

Conclusion and evaluation

(1)In 2007, it was accredited and accepted by the state seismological bureau

(2)Operating normally after being put into use

(3)Good electrical insulation, non-magnetic, wave absorption and transmission performance, to protect the normal operation of sensitive electronic communication equipment

Basalt fiber geogrid

Basalt fiber geogrid is a semi-rigid product made of high-strength basalt fiber by advanced weaving technology and coating treatment.

01 Main road of No. 2 Industrial Park in Alar City

Test Length: 2129m

Condition: drought, large temperature difference, high saline-alkali in soil

Conclusion and evaluation: High tensile strength, good resistance to bio-erosion and climate change, improved fatigue and cracking resistance, high-temperature rut resistance, low temperature shrinkage crack resistance and delaying reflection cracking

02 Yintai Avenue, Yizheng Economic Development Zone

Time: March 2014

Implementation plan: The old road was rebuilt and widened on both sides. The basalt fiber geogrid was laid at the joint of the old and new roads and the base of the old road.

Result

(1)High tensile strength to prevent cracks on asphalt pavement.

(2)Good compatibility with asphalt mixtures

(3)No long-term creep and good thermal stability

(4)Resistance to asphalt mixture at temperatures above 190 °C

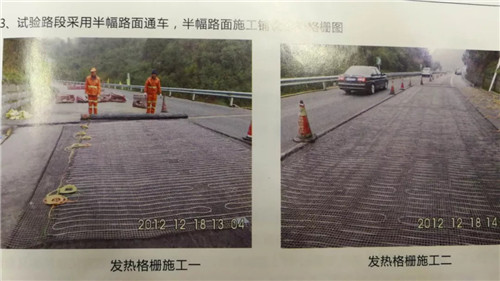

03G75 Lanhai Highway Guizun Section

Time: 2012

The selected Section

(1)freezing rain ice, long downhill, turns, prone to traffic accidents

(2)convenient power supply nearby

(3)salting and snow melting agent manually before, high cost and high risk

Implementation plan: Remove the old asphalt layer on the pavement, add a heating fiber geogrid (basalt fiber and carbon fiber mixed geogrid) on the AC-20 surface layer, and finally lay AC-13 (4cm)

Result

(1)snow and ice melting is obvious

(2)The heating geogrid stable in performance, reliable and durable, can be used for a long time.

(3)Intelligent power supply and temperature control, cause no deformation and stripping of asphalt pavement.

(4)The energy consumption of 1.5 km in snow and ice weather is 7,900 yuan/day - Back:Q&A十问十答玄武岩纤维系列(七)

- Next:Q&A十问十答玄武岩纤维系列(五)

Q&A十问十答玄武岩纤维系列(六)

Source: Time:2018-09-11