-

Q4

What are the special requirements for the raw material, basalt rock? What is the distribution of basalt in China?

Chemical composition requirement

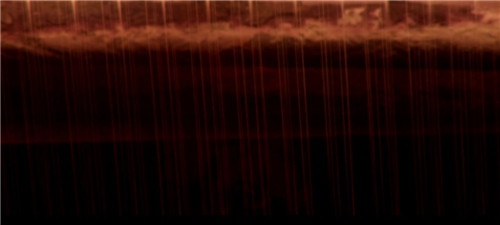

The continuous basalt fiber is made from pure natural basalt rock as unicomponent raw material, melted at 1500~1600°C and continuously drawn through the platinum-bismuth alloy bushing.

The production process of basalt fiber has certain requirements on the chemical composition and mineral phase of raw material, basalt rock. It also has certain requirements on the high temperature viscosity and crystallization temperature of the melt after melting. At present, when choosing the quarry, it should meets the chemical composition requirements of rock of the industry standard "JT/T776.1- 2010- Highway Engineering - Basalt Fiber and Its Products “

Chemical composition

Mass percentage

SiO2

48~60

Al2O3

14~19

CaO

5~9

MgO

3~6

Na2O+K2O

3~6

TiO2

0.5~2.5

FeO+Fe2O3

9~14

其他

0.09~0.13

Basalt distribution in China

01 The physicochemical properties of basalt

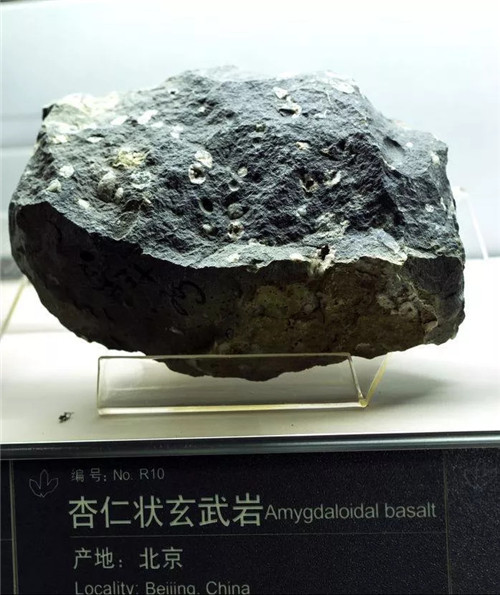

Basalt is a kind of basic extrusive rock whose chemical composition is similar to that of gabbro or diabase. The mineral composition is mainly composed of basic feldspar and pyroxene. The minor minerals are olivine, amphibole and biotite. Rocks are dark, generally black, sometimes grayish green and dark purple. It is a porphyritic structure, and the stomatal structure and amygdaloidal structure are common.

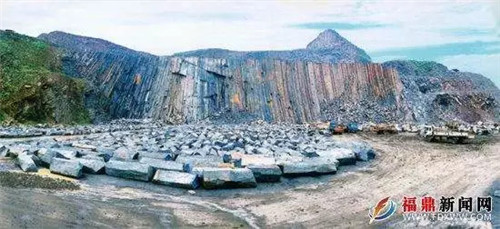

The volume density of the basalt is 2.8-3.3 g/cm 3. The compressive strength is very high, up to 300MPa. The basalt has high durability and many joints, and the joints are mostly pentagonal or hexagonal, forming columnar joints.

The chemical composition of basalt is SiO2, A12O3, CaO, MgO, Fe2O3+FeO, Na2O+K2O, TiO2, etc.

Among them, SiO2 and Al2O3 increase the high temperature viscosity of the melt, while CaO, MgO, Fe2O3, FeO, Na2O and K2O decrease the high temperature viscosity of the melt. Therefore, the basalt with different chemical composition has different high temperature viscosity, different melting temperature and molding temperature.

02 Distribution in China

The basalt reserves in Bailin Dazhang Mountain in Fuding City, Fujian Province, is 5000 million cubic meters. The ore is exposed to the surface and is jet black and graceful in color.

The basalts in Caidian Township, Luoyang City, Henan Province, are large and small round in size and rich in reserves. They are widely distributed about 50 cm below the surface and can reach a depth of more than 100 meters.

The reserves in Shandong Pingyi County, Yishui town is about 35 billion tons.

Mingguang City, Anhui Province, has proved the prospective reserves of 168 million tons of basalt, proven exploitable reserves of 34 million tons, the largest reserves in eastern Anhui Province, the annual mining and processing capacity of more than 1 million tons.

A large number of basalts are also distributed near the Tengchong volcanic group in Yunnan.

The Emei Mount basalt is mainly in the form of continental fissures or fissures-centers. It is distributed in the areas of Yunnan, Sichuan Huili County, and Jinsha River basin with a thickness of 1000-1500m.

03 Quality stabilization technology of basalt fiber

Basalt ore is widely distributed in China and has abundant reserves. However, not all basalt ore can produce continuous basalt fiber. According to a large number of research and development, the ore which can be directly used to produce continuous fiber is distributed in Shandong, Hebei, Inner Mongolia, Jilin, Jiangxi, Sichuan, Guizhou, Xinjiang, etc.

Professor Wu Zhishen, Director of Southeast University /Basalt Fiber production and application technology National Joint Engineering Research Center, proposed multi-compounding and equal-compounding concepts and theoretical methods for the problem of large dispersibility of natural ore.

Multi-mixing

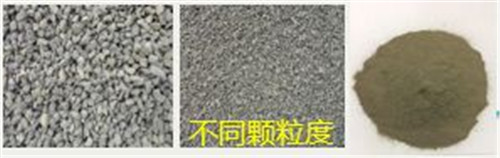

Equal-compounding study was carried out on the chemical composition, mineral phase and granularity of the ore from the same mining area and different mining areas:

?multi-compounding of ores from the same mining area but different spots;

?multi- compounding of ores from different mining areas

?Adaptation of granularity and multi-compounding uniformity

?To achieve the target

(for different products)

?Melting characteristics meet spinning requirements

?Chemical composition meets certain characteristic requirements.

?Mineral phase meets certain characteristic requirements

?Meet homogenization requirements

The main components of ore, such as SiO2, Al2O3 and Fe2O3, were realized to fluctuate < 1%. The fluctuations of the minor components, such as Na2O and K2O, were less than 0.5%, meeting the requirement of multi-compounding homogenization. - Back:Q&A十问十答玄武岩纤维系列(五)

- Next:Q&A十问十答玄武岩纤维系列(三)

Q&A十问十答玄武岩纤维系列(四)

Source: Time:2018-09-11