-

Q3

What are the characteristics and advantages of basalt fiber compared with other similar materials such as carbon fiber, lignin fiber, glass fiber?

Comparison

01 Main problems of common fiber materials in civil engineering application

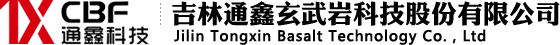

Carbon Fiber

High prices, limiting application in traffic field

Fragility, heat shrinkage and cold expansion, poor compatibility with traditional structural materials

?Too light weight, not conducive to structural vibration control

Lignin fiber

?It is an organic fiber, mainly used as a stabilizer in SMA mixture.

?Easy to absorb water, poor durability

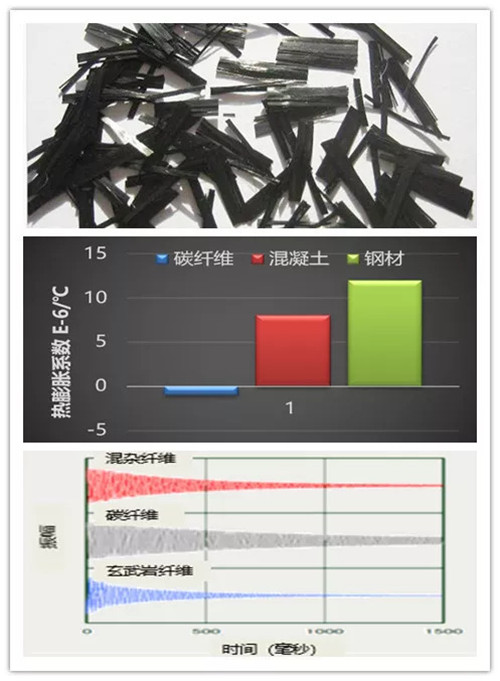

?Glass fiber, Aramid fiber

?Although the glass fiber is low in price, it has poor creep and corrosion resistance and cannot be used as a structural material.

?Although the strength of aramid fiber is high, the creep rate is large and expensive, and not suitable as a structural material.

02 Specific comparison between basalt fiber and other fibers

The difference between basalt fiber and other mineral fibers

In the field of highway engineering, in addition to the obvious difference in fiber shape and color, there are many qualitative differences in the interior.

01 Different acidity coefficient

The acidity coefficient is the ratio of SiO2+Al2O3 to CaO+MgO. The higher the acidity coefficient, the better the mechanical properties and the chemical stability, which is the main indicator for measuring the performance of mineral fibers. The acidity coefficient of basalt fiber is 5.7 times that of other mineral fibers.

02 Different function and effect

Compared with other mineral fibers, basalt fiber can not only increase the oil absorption rate by 320%, but also has the functions of reinforcement, bridging and anti-cracking, and better anti-rutting ability. Specific advantages are as follows:

wide operating temperature range

Excellent high temperature resistance and low temperature resistance, and its working temperature can be -269°C~650°C. Therefore, when it is mixed with asphalt at high temperature, its material properties will not be thermally degraded, and will not react with asphalt or dissolve, which can effectively change the situation that low temperature hardening and high temperature softening of asphalt, and can adapt to various high and low temperature road environments.

Excellent mechanical properties

It has high tensile strength and modulus, and its mechanical property is lower than carbon fiber, but higher than glass fiber and significantly higher than lignin fiber, which can effectively improve the reinforcement and toughness of asphalt mixture.

Good chemical stability

During the mixing of asphalt mixture, there is no chemical reaction with asphalt, and adapts to all kinds of pavement working environment.

Good anti-aging performance

Basalt fiber has excellent anti-aging performance, and it does not aging during the asphalt mixture mixing process and pavement working process, and does not deteriorate. Not affected by high temperature mixing of asphalt, so mineral fiber asphalt mixture can be 100% recycled.

Good water stability

Not absorbing water and not afraid of moisture, helpful to suppress oxidation and aging of asphalt and reduce the water damage of asphalt pavement.

Good insulation performance

The basalt fiber has good insulation performance, which will help the high temperature stability of the asphalt film and prevent its electrochemical corrosion.

Cost-effective

The price is 1/10~1/7 of carbon fiber, which is equivalent to the price of alkali-resistant glass fiber, but the comprehensive performance is superior and more cost effective. - Back:Q&A十问十答玄武岩纤维系列(四)

- Next:Q&A十问十答玄武岩纤维系列(二)

Q&A十问十答玄武岩纤维系列(三)

Source: Time:2018-09-11